Material Requirements Planning (MRP) is a critical process in the manufacturing industry that helps companies manage the materials needed for production. MRP involves determining what materials are needed, how much is needed, and when they are needed to meet production demands. It considers factors like lead times, inventory levels, and production schedules to ensure that materials are available when needed without excess inventory or shortages. MRP helps manufacturers optimize their production processes, minimize costs, and ensure timely delivery of finished products to customers. With this, it is important to keep the MRP running smoothly.

The planning repository refresh typically requires more time to process due to the volume of data it handles within the customer’s account. This can pose a challenge for an industry with a large volume of operations and records.

Listed below are the factors that have an impact on MRP performance and best practices to mitigate slowness:

1. Number of items and their respective location involved in the planning process.

Accounts containing numerous item-location combinations will invariably experience longer processing durations compared to those with fewer combinations. Providing a specific or average rate is challenging due to various factors such as rescheduling, transfer rules, and planning horizon. For example, an account with 600,000 item locations, incorporating rescheduling parameters, may experience prolonged processing times compared to another account with 5,000,000 item locations that does not utilize rescheduling

To make sure we are processing only the needed volume in MRP, users can:

a. Review their location records and ensure that only the locations that they want included in planning have the Include in Supply Planning checkbox enabled.

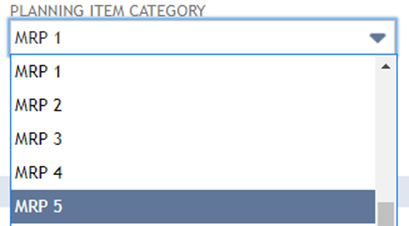

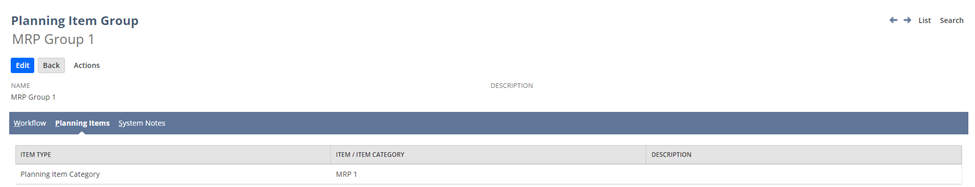

b. Make use of Planning Item Categories and Planning Item Group.

c. Inactivate or change the Supply Replenishment Method of items that does not need planning using MRP.

2. Length of Planning Horizon

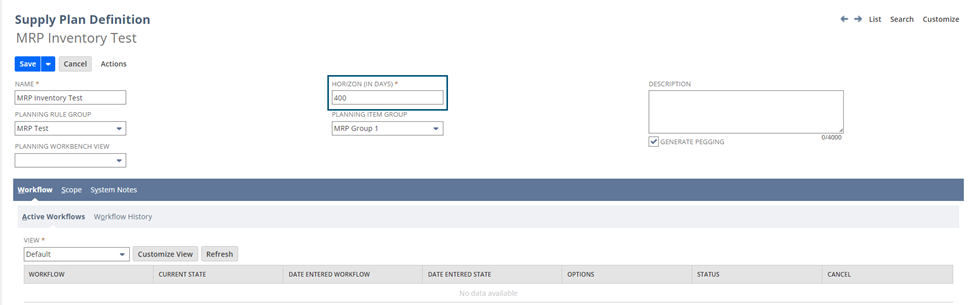

As noted in the preceding variable, this also applies to volume. Accounts with extensive datasets might experience sluggishness with an extended planning horizon. MRP may face challenges when processing an account with a planning horizon of 700 days and 200,000 item locations, yet it may successfully complete when the horizon is reduced to 400 days. Currently, there are no enforced limitations on the planning horizon’s length, but it is advisable to conduct testing to identify the most optimal value. Users may opt to reduce the horizon time.

3. Number of BOM Levels

Assembly Items with 6 or more levels experience decreased performance in the Material Requirements Planning process.

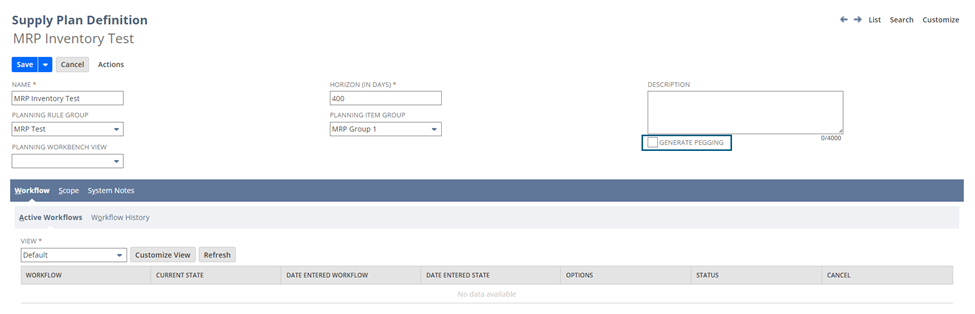

4. Pegging

Pegging is an extra functionality that connects demand to incoming supply and vice versa, adding an additional step to the MRP process. This is purely informative, and enabling or disabling it will yield the same planning results. If this is not needed, users can opt to disable the Generate Pegging checkbox on the corresponding plan definition.

5. Missing Item Location configuration records

Accounts utilizing the Advanced Item Location Configuration feature may encounter delays during their initial Planning Repository Refresh if their items lack Item Location Configuration records for their planning locations. The initial phase of the refresh, referred to as Repository Initialization, checks for the presence of Item Location Configuration records for all item-location combinations. If any are found to be missing, the system creates the required records, potentially leading to longer processing times, especially if numerous records are missing. To avoid this, user can perform CSV import (add or update) and create the necessary records in bulk.

Check related SuiteAnswers articles below: